Pat's Pump & Blower LLC

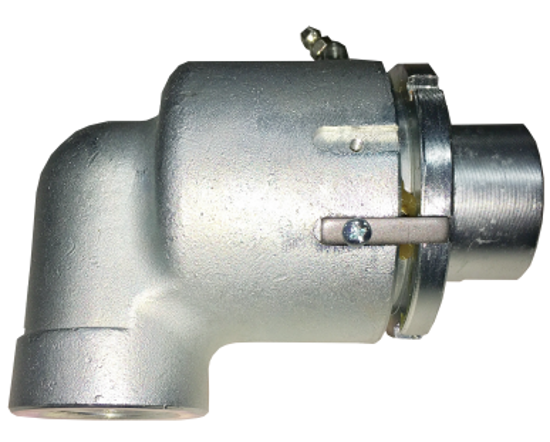

1-1/4" 90 Degree Hose Reel Swivel

1-1/4" 90 Degree Hose Reel Swivel

Couldn't load pickup availability

1. High-Quality Materials: These swivel joints are crafted using only the highest quality materials, ensuring a level of durability and performance that is superior to competitive models.

2. Housings: The housings are made from plated steel, which is investment cast. This choice of material and manufacturing process contributes to a longer lifespan for the swivel joint. The investment cast construction often leads to a more precise and reliable product.

3. Gland Nuts: Gland nuts are plated and heat-treated. This treatment enhances their wear resistance, ensuring that they last longer and withstand the demands of various applications.

4. Rotary Sleeve: The rotary sleeve is also plated and heat-treated for improved wear resistance. Additionally, the presence of two flat areas machined on the rotary sleeve allows for wrench-tightening, making assembly and maintenance more straightforward.

5. Backup Ring: The backup ring is nickel-plated to prevent rust. Rust prevention is crucial in maintaining the integrity and functionality of the swivel joint, especially in applications where exposure to moisture or corrosive environments is a concern.

6. Zerk Fittings: These fittings are included to facilitate lubrication. Proper lubrication helps to reduce wear and extends the life of the swivel joint, ultimately leading to less downtime and cost savings.

The advantages of TM® style swivel joints include longer life, reduced downtime, and enhanced wear resistance, all of which are essential in various industrial and fluid transfer applications. Proper maintenance, including regular lubrication, can further extend the lifespan and performance of these swivel joints, making them a reliable choice for industries and applications where durability and longevity are critical.

Share